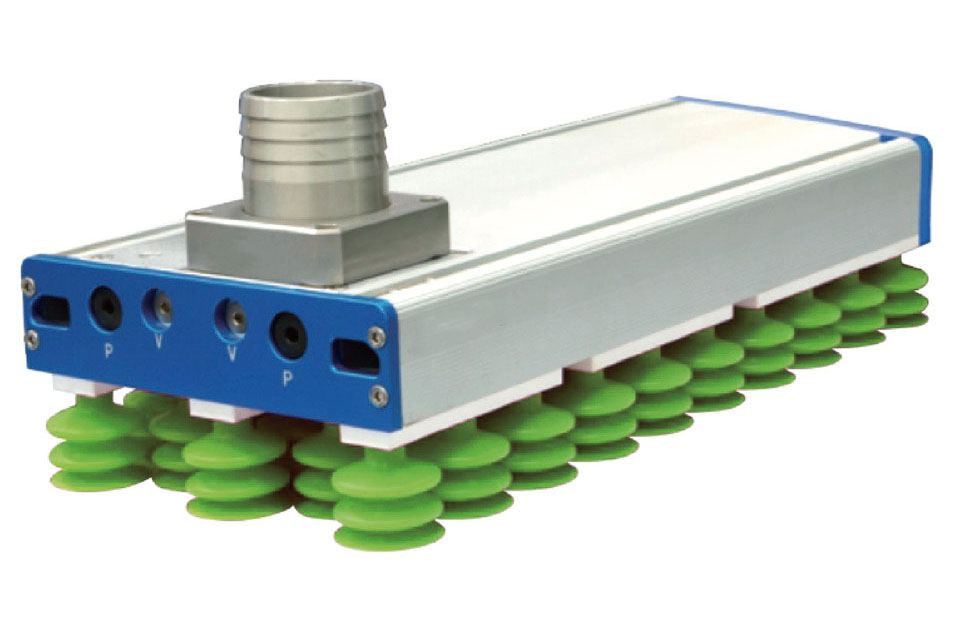

ATS/ATV200 Large area vacuum gripping system

SHARE

MODEL ATS/ATV200

Product Description

- ATS/ATV200 Vacuum Gripper is suitable for capturing products with different industry characteristics and can handle a variety of product specifications. It can be flexibly selected with standard suction cups or custom-designed suction cups based on actual application conditions, and different-sized suction cups can be freely combined and used in coordination.

- The optional self-closing valve technology addresses issues such as significant vacuum leakage, uneven surfaces, and irregular shapes of workpieces.

- The vacuum source adopts an integrated plug-in vacuum generator, resulting in lower air consumption, higher vacuum flow, and shorter vacuum creation time.

- The integrated plug-in vacuum generation device allows for individual configuration and quick disassembly according to changes in working conditions.

- The modular design makes it easy to maintain. Interfaces are reserved to directly attach functional components to the suction cup, optimizing processes and promoting environmental conservation and energy efficiency.

- The main body of the suction cup is made of materials such as aluminum alloy, engineering plastic, and carbon fiber composite, providing high strength and lightweight characteristics.

- The suction cup installation is straightforward, with a built-in T-shaped movable mounting slider that allows for fixing the suction cup, installing and using sensors, or assembling other components.

- Rubber sealing pad accessories can be quickly replaced.

3D File Downloads